Project log - CNC upgrade

Re: Project log - CNC upgrade

Hey look, it's a pile of parts:

Re: Project log - CNC upgrade

It looks like the design work is approaching doneness, finally. Thoughts?

-

GermTheGeek

- Posts: 13

- Joined: Tue Aug 23, 2011 11:47 pm

Re: Project log - CNC upgrade

The only word that comes to mind is "Sexy". Looks good.rsilk wrote:It looks like the design work is approaching doneness, finally. Thoughts?

Re: Project log - CNC upgrade

Update tiem!

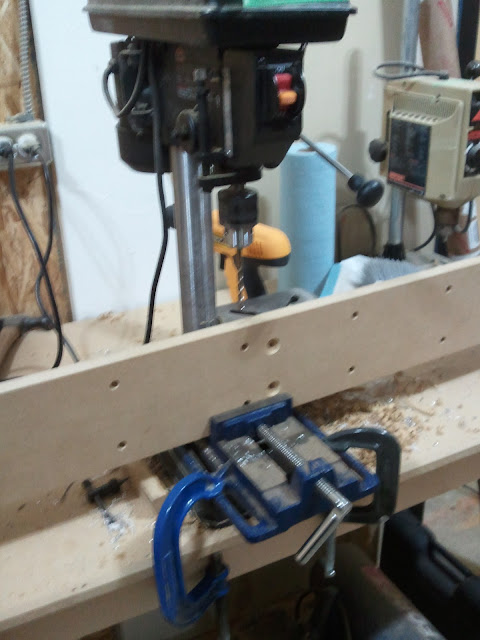

Got the X-axis rails fabricated and mounted, and a stand built for the torsion box.

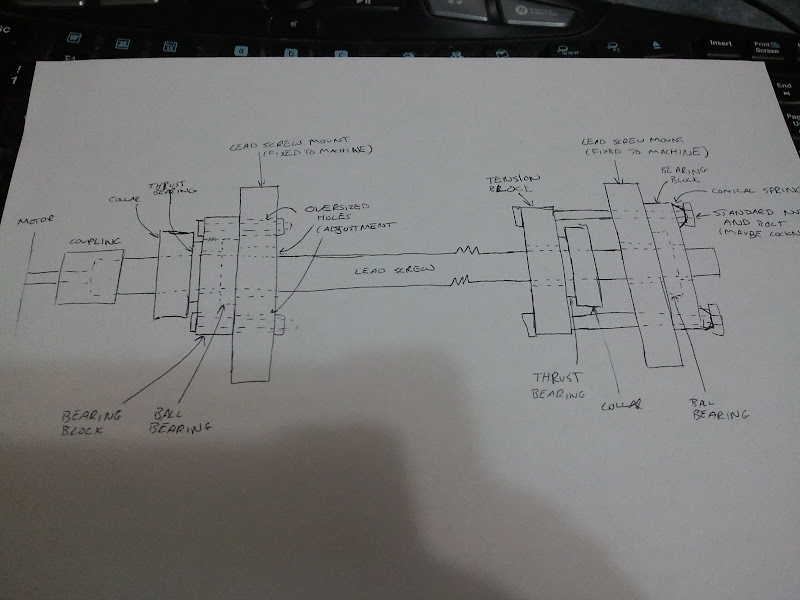

The lead screws and nuts have arrived, but we're still waiting on all the bearings and such before those can be mounted. In the meantime, I'm trying to figure out a way to tension the lead screws so they don't whip around during fast moves (and to keep backlash down). Here's one option:

Got the X-axis rails fabricated and mounted, and a stand built for the torsion box.

The lead screws and nuts have arrived, but we're still waiting on all the bearings and such before those can be mounted. In the meantime, I'm trying to figure out a way to tension the lead screws so they don't whip around during fast moves (and to keep backlash down). Here's one option:

Re: Project log - CNC upgrade

Hang on, that tensioner is stupid. This one's better.

Re: Project log - CNC upgrade

I don't know if it would simplify your design.. but you can cheat and use ball bearings (like skate bearings) as thrust bearings. I am currently doing this on my mill. (If you think about it, they also server that purpose in roller blades and skate baords). You could put your ball bearings on the outside of your bearing blocks, and back them with your collars (and maybe nuts to allow you to pre-tension before tightening the collars). Looking good though.

-Matt

-Matt

Re: Project log - CNC upgrade

It's a bit complicated this time around because I don't have nuts that mate with these leadscrews. Last time I used bog-standard 1/2-10 acme screw so nuts were cheap and easy to get. I'm using a 1/2-8 4-start screw this time around, so the nuts are hideously expensive. The thrust bearings aren't a big deal, and are only a couple of dollars each (and I'm poaching them from the old machine).

Re: Project log - CNC upgrade

That sounds reasonable, carry on

-Matt

-Matt

-

Conrad_Turbo

- Posts: 15

- Joined: Mon Sep 19, 2011 4:07 pm

Re: Project log - CNC upgrade

If you have any worries about flexing you can always laminate the MDF with a sheet of aluminum or steel depending on the configuration and which direction you see the flexing in. Looks pretty cool!

Re: Project log - CNC upgrade

I suppose I haven't posted an update in a while. Lots has happened!