Page 2 of 2

Re: The Solidoodle

Posted: Fri Jun 21, 2013 8:27 am

by Travis7s

Email sent...

Re: The Solidoodle

Posted: Fri Sep 13, 2013 9:59 pm

by Travis7s

Well our SD3 is running good, so thanks for the recommendation.

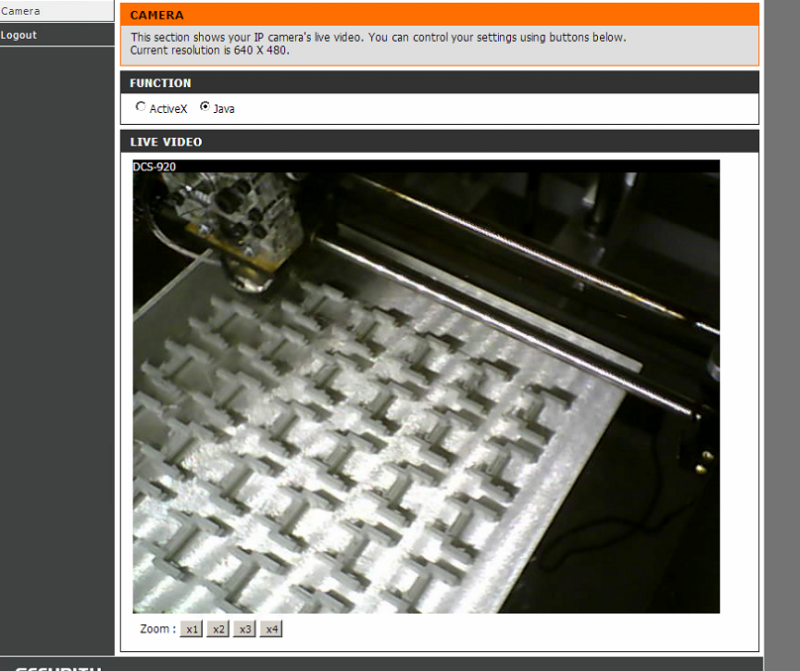

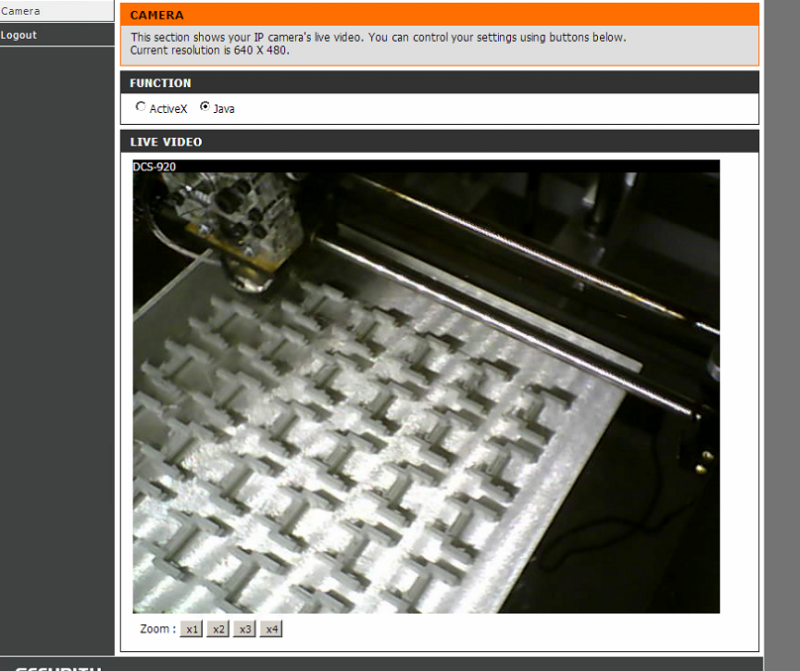

Ours had the same sticking issues, but once we upgraded to glass bed and built an enclosure its had a nearly 100% success rate. We run it almost all day and I even rigged up a webcam so I can view/remote control the SD during the night.

printing 30 pieces at once tonight

Re: The Solidoodle

Posted: Tue Sep 17, 2013 12:04 pm

by FingerTech

Nice! Happy with the quality I assume?

Re: The Solidoodle

Posted: Tue Sep 17, 2013 6:56 pm

by Kaldonis

Our glass bed didn't work out so well, though I'm not really sure why. Did you have to jump through any hoops to get your prints sticking well?

Re: The Solidoodle

Posted: Wed Sep 18, 2013 10:01 pm

by Travis7s

Quality is good enough for prototypes and stuff but not really for anything production. Main thing is to try and have as little support structure as possible as you never get as good a finish afterwards.

We went with 1/8" borosilicate glass from mcmaster, a little pricey at $25 a piece, but works great. I even dropped it once and it didn't break.

We had major issues with the stock aluminum/kapton. Unless you were printing something small in 'the sweet spot' near the center of the bed they wouldn't stick properly.

Switched to glass with hairspray and initially had problems so we tried sticking down one of those full size computer paper adhesive labels to the glass ( and used hairspray) and that worked awesome. Problem was it stuck so good that you would tear off part of the label when you removed the print.

I realized that the extra thickness of the label was the main reason it stuck so well, so I adjusted the z axis distance a little closer for just plain glass.

Now prints with glass and hairspray would always finish but the edges would curl and some of the layers would split.

Added a quick ugly enclosure made up of 1" foam insulation and that solved all of the curling/splitting issues. Ambient temperature is 56 C so thats probably not good for the stepper motor life, when I have some time I'll try to make a new enclosure out of lexan.

Re: The Solidoodle

Posted: Fri Jun 06, 2014 5:22 pm

by Travis7s

Solidoodle burns down house:

http://www.soliforum.com/topic/6608/bew ... d-printer/

Something to think about...